Reactive Ion Etching (RIE)

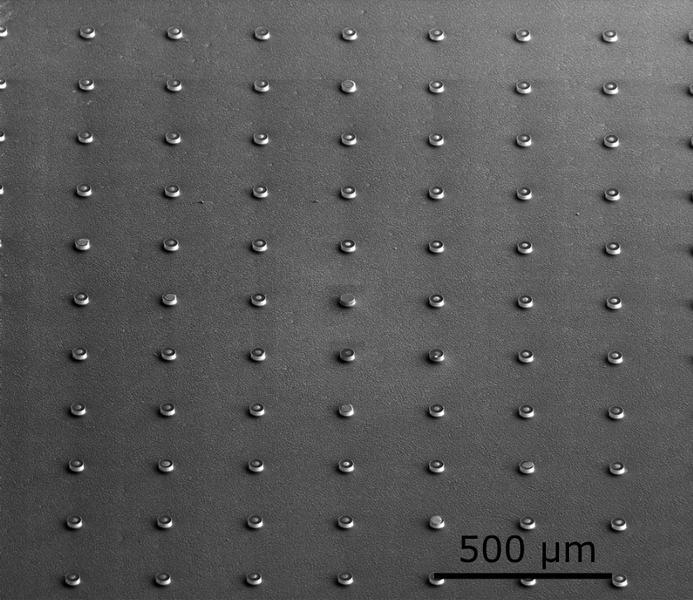

Reactive ion etching is a method where a masked material is subjected to a shower of ions often in the presence of reactive gasses for enhanced material removal. It is widely utilized in micro-electromechanical systems (MEMS) processes where high aspect ratio structures are required. Therefore, it is an important method of interest in the X-ray community for fabrication of high aspect ratio Fresnel Zone Plates (FZP). Recently, we are interested in using RIE for extending our fabrication capabilities. Main advantage of RIE compared to FIB is its parallel processing approach where one can fabricate many large structures in parallel. In the figure 6 a portion of a very large array of micro-pillars are shown.

Fig6: An array of micro-pillars etched in Silicon.