Kinoform Lenses

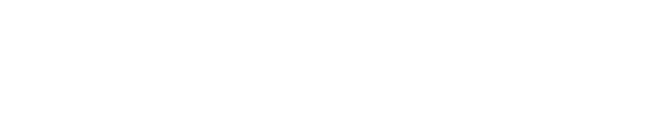

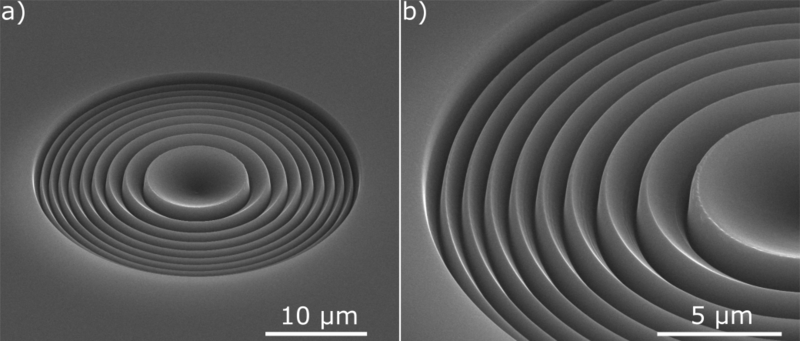

Kinoform lenses are diffractive/refractive optics taking advantage of both modalities to ensure maximum efficiency. In theory, a kinoform with ideal surface profile, made out of a non-absorbing but refracting material can have 100 % focusing efficiency. The required surface profile is parabolic and until recently, could only be fabricate with step approximations. We demonstrated that gray-scale direct milling IBL can be used effectively to fabricate kinoform lenses in a single step. To realize kinoforms with smooth surfaces another innovation was to utilize a nanocrystalline alloy of palladium and silicon. Amorphous or single crystalline materials are other good candidates for fabricating kinoforms. For instance in the Fig. 3, a (100) single crystal Si is shown to provide smooth lens surfaces after IBL. The aspect ratio is also quite high. This lens is expected to have more than 50 % focusing efficiency at 1000 eV. This figure is beyond anything possible with conventional FZPs.

Fig3: Overview (a) and close-up (b) SEM images of a kinoform fabricated in (100) single crystal Si substrate fabricated using gray-scale direct-write Ion beam lithography.